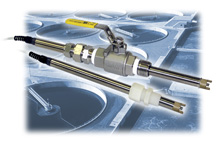

New Triton DO8 Dissolved Oxygen Analyzer System

Ideal for Drinking Water, Surface Water Monitoring, AquaCulture Municipal Wastewater Treatment, Industrial Water Treatment

Combining an advanced, highly intelligent multi-channel digital controller with a state-of-the-art fluorescence quenching (FQ) sensing element, the new Triton DO8 Dissolved Oxygen Analyzer System from Electro-Chemical Devices (ECD) is a highly reliable monitoring system solution for water treatment.

ECD’s C22 Multi-Channel Controller / Monitor integrated with the Triton DO8 Sensor creates a highly accurate oxygen analysis system. The C22 features a Multi-Bus architecture that allows up to four sensor inputs, six outputs and six relays. Simple, yet powerful, the compact C22 offers easy maintenance and lower cost of operation.

The highly accurate, low maintenance Triton DO8 Sensor couples precision FQ optical technology with intelligent microprocessor-based electronics. The self-monitoring DO8 stores calibration data within the sensor, which minimizes maintenance over long service intervals while providing stable, dependable DO measurement.

Offering top measurement accuracy, the Triton DO8 Sensor features a maximum error rate of less than 2 percent, repeatability of ±0.5 percent and resolution of 0.01 ppm or 0.01 percent saturation. It operates over a wide measurement range with three different outputs from 0 to 20 mg/l (0-20 ppm), 0-200 percent saturation or 0-500 hPa (0-6 psi).

The rugged Triton DO8 Sensor was specially developed for tough municipal and industrial water treatment environments and withstands ambient temperatures from -20 to 60°C (0-140°F) and records measurements at temperatures from -5 to 50°C (20-120°F). It withstands pressures up to a maximum of 10 bar (145 psi).

A proven fluorescence quenching method enables the Triton DO8 Sensor to determine the oxygen concentration in water. A circular layer of optically-active, oxygen-sensitive molecules is integrated into an easily replaceable cap. This durable layer is highly permeable to oxygen and rapidly equilibrates to its surroundings. The cap aligns the optically-active fluorescence layer above two optical components inside the sensor — an emitter and a detector.

After the sensor’s emitter flashes a green light at the layer, the layer fluoresces back a red light. The duration and intensity of the fluorescence are directly dependent on the amount of oxygen in the layer. With little to no oxygen in the layer, the response is longer and more intense. The presence of more oxygen, however, quenches (reduces) the fluorescence effect.

The Triton DO8 Sensor calculates dissolved oxygen values by continuously analyzing the oxygen level, water temperature and air pressure. Via digital communications, the DO8 sends DO data to ECD’s C-22 Controller, which provides a 4-20mA output signal to a water treatment plant’s control room. The RS-485 digital signal is nearly immune to common EMI/RFI noise that is typically a problem in many plant environments.

The Triton DO8 has no membranes to replace, no electrolytes to refill and no anode/cathode assemblies to service or replace, making it lower maintenance than amperometric sensors. The only service required is the simple replacement of the DO8’s sensor cap, which lasts two years or longer, and the occasional wiping of the sensor head with a damp rag.

Links of Interest

![]() Triton DO8 Oxygen Analyzer System

Triton DO8 Oxygen Analyzer System

![]() Triton DO8 Oxygen Analyzer System Brochure

Triton DO8 Oxygen Analyzer System Brochure