OIW80 Oil-In-Water Analyzer

For Immediate Release Monitoring Oily Water Leaks and Effluent From Industrial & Municipal Systems With Fluorescence Sensing Analyzer H2 Production, Chemical Plants, Oil/Gas Refinery Effluent, Electric Power Generation, Municipal Wastewater, Storm Water Systems, Airports & Warehouses Anaheim, CA—July 22, 2024—Process and plant engineers concerned about meeting U.S. Environmental Protection Agency (EPA) pollution requirements […]

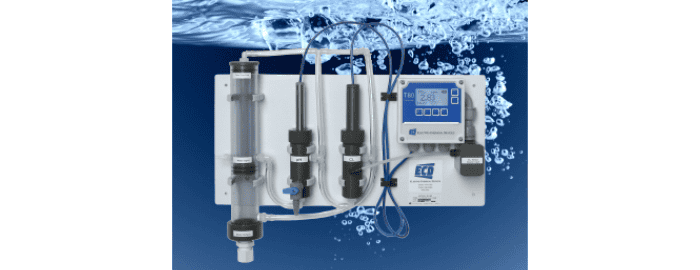

Easy-Button Free Chlorine Analyzer

See Us at AWWA ACE 2024 Anaheim, CA, Booth 2180, June 10-13 For Immediate Release Easy-Button Free Chlorine Analyzer Delivers Performance With Less Maintenance and Lower Cost-of-Ownership Ideal in Drinking Water, Wastewater and Industrial Water-Based Processes Anaheim, CA—May 20, 2024—Busy municipal water plant engineers and techs will appreciate how the precision FC80 Series […]

TC80 Total Chlorine Analyzer

See Us at AWWA ACE 2024 Anaheim, CA, Booth 2180, June 10-13 For Immediate Release Easy, Economical Total Chlorine Measurement With Highly Intelligent ECD TC80 Analyzer Ideal in Drinking Water, Wastewater and Industrial Water-Based Processes Anaheim, CA—April 10, 2024—Engineers responsible for municipal drinking water and/or wastewater, as well as a wide variety […]

Explosion-Proof Liquid Analyzer for Hazardous Areas

Explosion-Proof Liquid Analyzer for Hazardous Areas Measures Specific Ions, pH, ORP, DO and More ATEX, IECex, FM and CSA Certified For Petrochemical & Other Industrial Processes Anaheim, CA—March 27 2024—The rugged, modular, versatile X80 Universal Transmitter and S88 Intelligent Sensors from Electronic Component Devices, Inc. (ECD) deliver an easy to-use plug-n-play, reliable precision liquid measurement analyzer […]

Protecting Surface & Tank Water Storage Systems With Intelligent Dissolved Oxygen (DO) Analyzer

Protecting Surface & Tank Water Storage Systems With Intelligent Dissolved Oxygen (DO) Analyzer Ideal for Maintaining Healthy Municipal Water Storage Systems, Lakes, Streams, Ponds, Fisheries & Hatcheries and Aquatic Plant Life Anaheim, CA—February 21, 2024—Municipal water systems engineers concerned about protecting large surface and tanks water storage systems, will want to consider how […]

Double-Play Sensor for Nutrient Nitrogen Monitoring In Wastewater Effluent and Surface Water Storage

Double-Play Sensor for Nutrient Nitrogen Monitoring In Wastewater Effluent and Surface Water Storage Anaheim, CA—February 7, 2024—With its versatile design that monitors nitrogen (NH4) as ammonium or as nitrate, the precision family of HYDRA-DS Analyzers from Electro-Chemical Devices (ECD) simplifies the accurate measurement of harmful nutrients in wastewater treatment effluent flows and in surface water […]

Modular Liquid Analyzer Transmitter & Sensors Stand Up To Harsh Hazardous Area Environments

Electro-Chemical Devices For Immediate Release Modular Liquid Analyzer Transmitter and Sensors Stand Up To Harsh Hazardous Area Environments ATEX, IECex, FM and CSA Certified Analyzer Measures pH, ORP, Specific Ions, Dissolved Oxygen, Turbidity, Conductivity, Resistivity and Chlorine Anaheim, CA—December 18, 2023—Process and plant engineers responsible for hazardous area operations will find the modular X80 […]

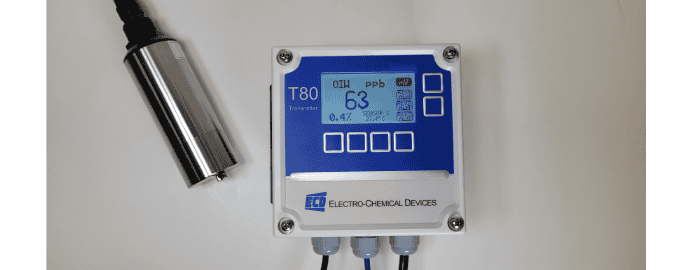

Highly Intelligent Oil in Water Analyzer Accurately Detects Petroleum Contamination in Industrial & Municipal Water Systems

Electro-Chemical Devices For Immediate Release Highly Intelligent ECD OIW80 Oil in Water Analyzer Accurately Detects Petroleum Contamination in Industrial & Municipal Water Systems Refinery Effluent, Chemical Process Cooling, Electric Power Generation, Rivers, Lakes, Oceans, Harbors, Municipal Stormwater & Wastewater, Airports & Warehouses Anaheim, CA—November 13, 2023–Engineers responsible for safeguarding water systems against oil […]

Measuring Alkalinity With CA900 Analyzer Optimizes Water Piping Corrosion Prevention Systems

Electro-Chemical Devices For Immediate Release Measuring Alkalinity With CA900 Analyzer Optimizes Water Piping Corrosion Prevention Systems Helps Extend Municipal Water Piping Life and Enhance Water Quality Anaheim, CA—October, 23, 2023—Municipal water engineers tasked with preventing pipe corrosion by carefully balancing system pH/Alkalinity/DIC levels will find that the advanced CA900 Alkalinity Analyzer from […]

Reagent-less FC80 & FC80X Free Chlorine Analyzers Minimize Maintenance & Cut Cost of Ownership

Anaheim, CA—August 21, 2023—Water process and plant engineers bogged down by the monitoring and frequent replacement of sensor reagents will find that they can now save time and money with the FC80 Free Chlorine Analyzer and FCX80 Free-Chlorine Analyzer from Electro-Chemical Devices (ECD), which are suitable for either general-purpose use or for use in hazardous […]