Easy to Use, Economical CA-6 Colorimetric Silica Analyzer for Boilers

Ideal for High Pressure Boiler Industrial Water In Power Generation Plants

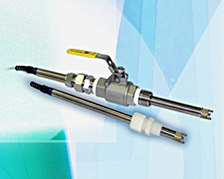

Maintaining boiler water quality is easier than ever with the user-friendly CA-6 Online Analyzer from Electro-Chemical Devices, which uses colorimetric technology to accurately and reliably perform silica measurements.

When boiler water is contaminated with silica, scaling can occur. Silica picked up by boiler steam can be deposited on generator turbines and lead to blade corrosion and diminished boiler efficiency. Effective monitoring of silica levels in boiler water helps to determine how well a boiler’s demineralizer system is working, protecting equipment and ensuring that power generation systems are functioning as safely and economically as possible.

The CA-6 Analyzer is available in models measuring silica at 0-1.0 mg/L, 0-10.0 mg/L or 0-60 mg/L. It can also utilize photometric differential absorbance to analyze over 20 other common parameters in addition to silica including: aluminum, phosphate, nitrogen, iron and sulfate. It operates at a wide temperature range of 5-50°C and offers repeatability of ±2% on the absorbance value if the turbidity <80 NTU and drift of ±2% per month on the absorbance measurement.

Lightweight and easy to install, the versatile CA-6 precision online sequential sampling analyzer weighs less than 40 pounds. It can be wall mounted or simply set on a bench using the optional Bench Top Stand. After the sample, waste and reagent lines have been connected to the analyzer and provided with power, the CA-6 will begin its preprogrammed analysis sequence. The CA-6 is available with up to 4 channels (optional) each from a separate sample point. A simple, user-friendly menu structure and touchscreen interface makes it easy to access information or customize analyses.

The highly accurate CA-6 Analyzer saves labor and money when compared to online ISE measurements that require significant sample conditioning. With the CA-6, the result is a faster, more accurate measurement requiring fewer consumables with less waste to reduce overall operating costs.

The CA-6 Analyzer features a user-friendly touch-screen display that shows the measured parameter, analyzer status, percent reagent volumes, time and the menu bar, which provides access to the Run, Display, Program, Service and Help menus. It includes two alarm relay outputs and a 4-20 mA channel that connects with PLC’s or distributed control systems.

The CA-6 is rugged and reliable. It is enclosed in an epoxy powder coated, cold rolled steel cabinet and features two separate compartments to isolate liquids and electronics. The liquids enclosure houses all the components necessary for sampling and reagent flow, mixing and reaction stages (sampling pump, reagent micro-pumps and colorimetric reaction cell). The electronics enclosure contains the main power supply, the controller printed circuit board assembly and the touchscreen interface.

The CA-6 Analyzer makes it easy to create customized analysis routines and access results via the touchscreen unit’s simple menu structure and function commands. It can be programmed with numerous analysis configurations, depending on the accessories and the number of micro-pumps mounted in the liquids enclosure.