Steam-Sterilizable Sensor Electrodes Beat the Heat To Measure pH, DO & ORP in Pharma Environments

Anaheim, CA—April 18, 2023—Pharmaceutical and biotech process and plant engineers who need accurate process measurements for pH, DO or ORP under sterile conditions for R&D or in pilot or full production lines will find the SE Steam Sterilizable Sensor Electrodes from Electro-Chemical Devices are an ideal solution in these demanding environment applications.

ECD’s advanced SE Series pH, ORP and DO Sensor Electrodes are 12 mm diameter size and suitable for steam sterile environment processes. The pH and ORP electrodes are gel filled, sealed combination devices. They provide many months of service with their robust design that and stable double-junction reference electrodes. Similarly, the galvanic dissolved oxygen electrode also provides stable output over months of service.

The pharmaceutical and biotech industries have numerous process applications requiring the measurement of pH and conductivity. Not all industrial liquid analyzer electrodes, however, are designed for this rugged high-temperature, and often high-pressure environment, which is necessary to ensure equipment cleanliness. The ECD steam Sterilizable Electrodes (SE) and Sterilizable Fittings (SF) provide a reliable and economical solution for these measurements.

In meeting these sterile requirements, ECD’s SE Series Electrodes provide users with a wide measurement range suitable for popular applications: The pH electrode’s sensor tip relies on a low radius glass bulb sensor tip and measures over a range of 0.00-14.00 pH. The DO electrode features a Teflon® PFA membrane sensor tip with a measurement range of 0 to 20 ppm. The ORP (REDOX) electrode’s platinum sensor tip offers a range to ±1500 mV.

Designed for demanding process environments, all three SE Series Sensor Electrodes feature designs featuring wide operating temperature ranges from -5 to 130-135°C (-23 to 266-275°F) depending on the sensor type. The pH and ORP sensors withstand pressures to 100 psig, while the DO sensor withstands pressures to 30 psig.

Wetted electrode materials include AISI 316L stainless steel with a surface finish of Ra=0.8 µm (optional Ra=0.4 µm) and include FDA compliant O-ring seals. The 25 mm (0.98 in) port fitting is available with a standard 40.64 mm (1.6 in) insertion length, common on most installations, or the longer 50.6 mm (2.4 in) insertion length needed on some B. Braun vessels.

Various insertion lengths are available in the SE Series electrodes to meet the requirements of both top entry and side entry reactors. The standard insertion lengths are 120 mm (4.72 in), 225 mm (8.85 in) and 360 mm (14.17). The process connection of the electrical connectors is PG 13.5. This broad offering allows the same SE Series pH, ORP and Dissolved Oxygen electrodes to be used in R&D pilot reactors or large scale production vessels.

The SF Series fittings for the SE Series electrodes are available in a variety of installation styles, including the 25 mm (0.98 in) port fitting and several sanitary flange styles. The SF Series complies with the basic criteria for CIP clean in place (CIP) and steam in place (SIP) applications, which were developed by the European Hygienic Equipment Design Group (EHEDG).

Sanitary flange fittings are available in 38.1 mm (1.5 in), 50.8 mm (2 in) and 76.2 mm (3 in) diameters and various insertion depths. All fittings have an electrode guard that protects a 120 mm (4.72 in) pH electrode from breakage. The guard has no value for the longer length sensors so the fittings can be ordered without the guard as an option.

Anaheim, CA—January 27, 2021—Plant engineers responsible for water and wastewater treatment in municipal and industrial plants will find that Electro-Chemical Devices (ECD) now offers them two different highly accurate and reliable solutions to measuring total organic carbon (TOC) levels to protect water quality.

Anaheim, CA—January 27, 2021—Plant engineers responsible for water and wastewater treatment in municipal and industrial plants will find that Electro-Chemical Devices (ECD) now offers them two different highly accurate and reliable solutions to measuring total organic carbon (TOC) levels to protect water quality. Anaheim, CA—June 29, 2021—Engineers responsible for municipal ground or surface drinking water supplies, storage, treatment and distribution systems in remote locations or close to population centers will find the modular, Cloud-ready LQ800 Multi-Channel Control System offers them a complete measurement and control solution that provides over 50 analytical measurements, as well as liquid flow, level and temperature data.

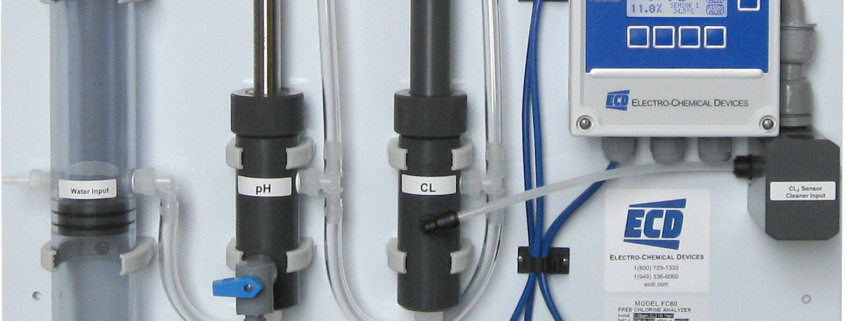

Anaheim, CA—June 29, 2021—Engineers responsible for municipal ground or surface drinking water supplies, storage, treatment and distribution systems in remote locations or close to population centers will find the modular, Cloud-ready LQ800 Multi-Channel Control System offers them a complete measurement and control solution that provides over 50 analytical measurements, as well as liquid flow, level and temperature data. Anaheim, CA—May 25, 2021—Process and plant engineers responsible for contaminant-free in-plant water treatment systems for heating, cooling, rinsing, washing and effluent treatment will find that the CE800 Series Analyzers from Electro-Chemical Devices (ECD) detect a wide range of contaminants, which contribute to the build-up of corrosion and scale in boilers, turbines, piping and other expensive equipment that requires maintenance and shortens life.

Anaheim, CA—May 25, 2021—Process and plant engineers responsible for contaminant-free in-plant water treatment systems for heating, cooling, rinsing, washing and effluent treatment will find that the CE800 Series Analyzers from Electro-Chemical Devices (ECD) detect a wide range of contaminants, which contribute to the build-up of corrosion and scale in boilers, turbines, piping and other expensive equipment that requires maintenance and shortens life.