Anaheim, CA—February 7, 2024—With its versatile design that monitors nitrogen (NH4) as ammonium or as nitrate, the precision family of HYDRA-DS Analyzers from Electro-Chemical Devices (ECD) simplifies the accurate measurement of harmful nutrients in wastewater treatment effluent flows and in surface water storage systems, including ponds, lakes, reservoirs, canals and streams.

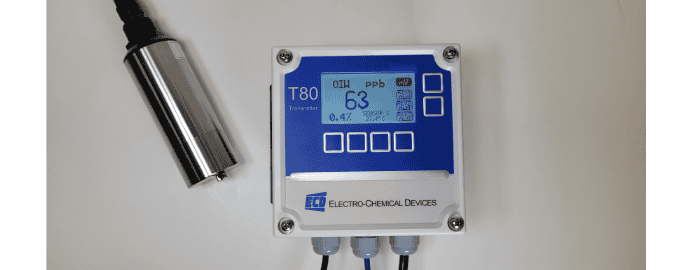

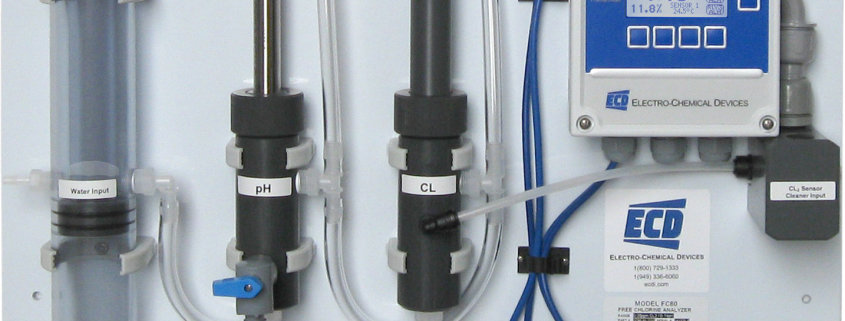

The HYDRA-DS Analyzers from ECD feature an advanced ion selective electrode (ISE) sensor, which is especially designed for multiple parameter nutrient nitrogen water quality measurements. This versatile double-duty ISE sensor seamlessly connects with either ECD’s intelligent T80 Transmitter or LQ800 Multi-Channel Transmitter to provide a total system solution for highly effective and economical nutrient management.

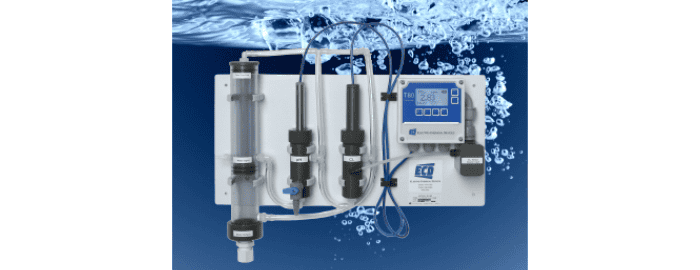

ECD’s HYDRA-DS plug-n-play family of analyzers relies on ISE sensors with digital signal conditioners for the trouble-free measurement of ammonium as nitrogen (NH4+-N) and/or the measurement of nitrate as nitrogen (NO3–-N). They feature auto-compensation circuitry for interfering ions and temperature compensation, rugged PVC construction with easily replaceable electrodes and a built-in spray cleaner that minimizes expensive technician maintenance for a lowest total cost of ownership.

Developed for demanding municipal wastewater treatment and water storage applications, the HYDRA-DS Analyzers are ideal for aeration basins, primary or secondary clarifiers, denitrification and final effluent monitoring. For environmental waters, they are useful in water storage applications such as lakes, reservoirs or ponds and to control nutrients from agricultural run-off flows into canals, storage basins and ground water aquifers and wells.

HYDRA-DS Ammonium Analyzers

The HYDRA-DS Ammonium Analyzer is designed to monitor the nutrient load (NH4+) directly in the aeration basin of a wastewater treatment plant. Its powerful sensor uses ISE technology to measure the ammonium, potassium and pH levels. Its self-compensating design automatically compensates for the pH-dependent concentration equilibrium and potassium ion interference on the ammonium electrode.

ECD Family of HYDRA-DS Analyzers

The ammonium sensor measures the concentration of dissolved ammonium as nitrogen (NH4+-N) in water. The sensor uses three electrodes to determine the NH4+-N concentration, an ammonium ion electrode, a potassium ion electrode and a pH electrode. It is designed for use in all kinds of municipal wastewater or wherever ammonium is present in water.

The ammonium ion electrode performs the primary measurement. Any potassium ion in the sample, however, generates a positive interference in the measurement because of its similar size and charge to the ammonium ion. The HYDRA-DS Analyzer’s highly intelligent transmitter self-compensates by adjusting the signal for this potassium interference and eliminates it from the measurement of ammonium for superior accuracy and reliability.

The ammonium ion electrode measures the ammonium ion (NH4+), not ammonia (NH3). The ammonium ion and ammonia coexist in a pH dependent ratio in solution. The more acidic pH values favor the NH4+ and the more basic values favor dissolved ammonia gas, NH3. The pH electrode measures the pH level, and the transmitter calculates the total NH4+-N concentration based on the pH versus the NH4+ concentration profile stored in the instrument.

HYDRA-DS Nitrate Analyzers

The HYDRA-DS Nitrate Analyzers are designed to monitor the nitrification process directly in a wastewater treatment plant’s aeration basin or clarifier unit. Its advanced sensor uses ISE technology to measure the Nitrate. Also featuring a self-compensating design, the HYDRA DS automatically eliminates Chloride ion interference for high accuracy and reliability.

The HYDRA-DS Nitrate Analyzers measure the concentration of dissolved nitrate as nitrogen (NO3-N) in water. The sensor uses two electrodes to determine the NO3-N concentration, a nitrate ion electrode and a chloride ion electrode. It is designed for use in all kinds of water ranging from municipal and industrial wastewater treatment.

For example, nitrogen typically enters a municipal wastewater treatment plant as ammonia/ammonium compounds. Nitrification oxidizes the toxic ammonium ion into a much less toxic nitrate ion using an aerobic activated sludge process. De-nitrification reduces the nitrate ion (NO3) to nitrogen gas (N2) by an anoxic reaction in the same treatment basin or in a separate anaerobic digester. The NO3-N measurement can optimize the methanol being fed to the digester, minimizing cost, and also provides a trend of the total nitrogen in the effluent.

The nitrate ion electrode performs the primary measurement. A second electrode measures the chloride ions in the sample. The chloride ion, because of its similar size and charge to the nitrate ion, causes a positive interference in the measurement. The chloride ion electrode

ECD Family of HYDRA-DS Analyzers

measures the amount of chloride ion present in the sample and the intelligent transmitter subtracts the appropriate amount of signal from the nitrate measurement.

The HYDRA-DS sensor rapidly measures NO3-N and NH4-N from 0.1 to 14,000 ppm with a response time of 1 minute (T90) and an accuracy of ±3% of reading, dependent on calibration. It operates over a wide temperature range from 32 to 122°F (0 to 50°C). Its highly intelligent transmitter includes an easy-to-read backlit display and comes with two 4-20mA outlets and three SPDT alarm relays. An integral automated sensor spray cleaner reduces biofilms to enhance accuracy and reduce sensor maintenance.

The HYDRA-DS Analyzer rapidly measures NH4+-N from 0.1 to 14,000 ppm with a response time of 1 minute (T90) and an accuracy of ±3% of reading, dependent on calibration. It also operates over a wide temperature range from 32 to 122°F (0 to 50°C). Its intelligent transmitter also includes an easy-to-read backlit display and comes with two 4-20mA outlets and three SPDT alarm relays. An integral automated sensor spray cleaner reduces biofilms to reduce sensor maintenance.

About ECD Analyzers

ECD Analyzers is a subsidiary of Electro-Chemical Devices, Inc., which is a manufacturer of liquid analytical process instrumentation. Founded in 1977, ECD has been in business for over 40 years and has built its industry leading reputation by its commitment to customers through this basic approach: Provide quality products, develop technical innovations and provide responsive, knowledgeable service.

ECD Company Contact: Eric Kim ● ECD Address: 1500 N. Kellogg Dr., Anaheim, CA 92807 USA

Web: www.ecdi.com ● Email: [email protected] ● Tel: 800-729-1333 Tel: 714-695-0051 ● Fax: 714-695-0057