You’ll find ECD’s innovative technologies and advanced analyzer instruments are suitable for a wide range of applications in diverse industries, which have been documented and profiled on major industry web sites, trade publications and technical journals.

Ultra-Pure Water Analyzer Detects Trace Sodium Levels

Ultra-Pure Water Analyzer Detects Trace Sodium Levels – Precision PPB Level NA Monitoring for Use in Pharmaceuticals, Food/Beverage, H2 Electrolysis, Steam Turbine and Boiler Water, Electronics, Refineries & More

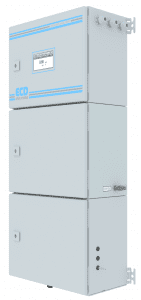

Anaheim, CA—January 25, 2022—Process and plant engineers requiring ultra-pure or high purity water for a wide range of ingredient and rinsing or washing or feed water applications ranging from pharmaceuticals to food/beverage to green hydrogen (H2) electric power will find the NA6 Sodium Analyzer from Electro Chemical Devices (ECD) sets the standard in providing accurate measurement, reliability and ease of use.

Anaheim, CA—January 25, 2022—Process and plant engineers requiring ultra-pure or high purity water for a wide range of ingredient and rinsing or washing or feed water applications ranging from pharmaceuticals to food/beverage to green hydrogen (H2) electric power will find the NA6 Sodium Analyzer from Electro Chemical Devices (ECD) sets the standard in providing accurate measurement, reliability and ease of use.

Many consumer products and industrial processes rely on ultra-pure or high-purity water. They include pharmaceutical water for injection (WIF), beer or other beverages and food products where water quality affects taste, as well as the sanitary rinsing of clean-in-place (CIP) equipment. Other industrial applications include H2 electrolysis production for green electric power, corrosion prevention in steam turbines for conventional electric power generation, steam boilers in refineries, as well as semiconductor fabrication, glass production and metal plating.

With an advanced glass electrode sensor that measures sodium in water to the parts per billion (ppb), parts per million (ppm) or milligram per liter (mg/l) levels, the ECD NA6 Sodium Analyzer is the flexible water quality assurance tool. The sodium sensor’s measurement range of 0.1 to 10 ppb is based on the proven accuracy of ECD’s sodium glass electrode sensor for the online potentiometric detection of low ppb traces of sodium.

When exposed to raw process or treated process water, ECD’s sodium glass electrode sensor produces an electronic signal potential proportional to the log of the sodium concentration. The sample is exposed to a reagent vapor, which raises the sample pH to 11 to eliminate any pH or ammonium interferences that would affect measurement accuracy. Highly reliable too, reproducibility is ±0.2 ppb or 5%, whichever is greater at constant temperature.

The NA6 Analyzer features a tri-compartment design for reliability and safety. The electronics and user interface display are in the top compartment, with the calibration solutions for autocal in the middle compartment and the wet sample housed in the bottom of the unit. The electronics are always dry and safe from moisture for superior reliability.

NA6 Sodium Analyzer Page 2 of 2

The NA6 features a dual-function design for maximum user flexibility by plant technicians. It features a T90 180 sec (0 to 10 ppb) delay time when in continuous operation. The water analyzer’s “grab sample” capability also enables the unattended analysis of manually collected samples. The results of external samples are stored in the analyzer’s data logger, which includes time and date stamping information for history logging.

For easy installation, the ECD NA6 Analyzer is ready to go right out of the box. It takes a single technician less than 30 minutes with no special training or tools to get the NA6 up and running. All that needs to be done is connect the power, the sample line and the reagent lines. The analyzer is then fully operational.

The NA6 analyzer offers a choice of a manual 1-2 point calibration mode or a 2-point automatic calibration mode. The 2-point automated calibration mode minimizes operator intervention and ensures accurate results are obtained. Free selectable calibration intervals are available too. The results of the last ten calibrations are stored in the analyzer’s internal data logger.

With its built-in color touchscreen user interface with multi-lingual capability, the NA6 Analyzer is highly intuitive. It displays measured values and status information in a large easy-to-read format. The design provides full access to menus and functions. The built-in data logger comes with USB download capability.

Two 4-20 mA data outputs are provided with the NA6 Analyzer, which are compatible with Modbus RTU485 plant control system communications. Three onboard SPDT relays are programmable to set alarms. The standard power supply is 120/240 VAC, 50/.60 Hz, with an available 24 VDC optional configuration.

The rugged, long-life NA6 Analyzer operates over a wide temperature range from 41 – 122 °F (5 to 50 °C). Ingress protection is IP54 compliant. For outdoor use, an optional cabinet enclosure is available for harsh weather conditions.

Process WorldWide, Intelligent Sensor Detects Petroleum Leaks to Prevent Water Contamination, Nov. 25

Electro-Chemical Devices (ECD) has introduced its new self-cleaning oil-in-water sensor – OIW80 which helps municipal water and wastewater facilities as well as industrial plants to quickly and accurately detect oil in water leak incidents. This technology helps one to take quick action in order to prevent contamination of drinking water, fouling of batch processes, damage to plant equipment or contamination of sensitive water ecosystems.

Electro-Chemical Devices (ECD) has introduced its new self-cleaning oil-in-water sensor – OIW80 which helps municipal water and wastewater facilities as well as industrial plants to quickly and accurately detect oil in water leak incidents. This technology helps one to take quick action in order to prevent contamination of drinking water, fouling of batch processes, damage to plant equipment or contamination of sensitive water ecosystems.

Engineers at municipal water or wastewater facilities and industrial plants will find that the new OIW80 Sensor from Electro-Chemical Devices (ECD) helps them to quickly, accurately and economically detect oil in water leak incidents requiring fast response actions to prevent further contamination of drinking water, fouling of batch processes, damage to plant equipment and/or contamination of sensitive water ecosystems.

The highly intelligent, precision sensor reliably measures oil in water over a range of 0 to 30 ppm (mg/L), and it can be factory preconfigured to measure oil in multiple ranges or easily set in the field, states the company. This rugged, high-performance responsive sensor operates over a temperature range from 41 to 113oF (5 to 45oC) to quickly detect leaks and alert plant technicians.

Designed for demanding and/or dirty plant environments, the highly dependable sensor features a built-in wiper cleaning system to remove bio solids and films that might cloud the sensor window’s visibility. The sensor features a built-in automatic screen window wiper that reduces technician manual checks and the frequency of scheduled maintenance cleanings.

The heavy-duty construction of the sensor’s rugged housing utilizes strong, corrosion resistant Stainless Steel (standard) or optional Titanium and meets the IP68 water ingress standard. Every aspect of the sensor’s design has been tailored for years of reliable operation and trouble-free service in the demanding wet environments typical of municipal and industrial water and wastewater treatment applications, adds the firm.

The versatile sensor features built-in RS485 serial communications and is Modbus/RTU compatible. Users can choose from ECD’s two-channel T80 Universal Transmitter or ECD’s eight-channel LQ800 controller, or a wide range of RS485/Modbus compatible third-party controllers. Up to eight LQ800 controllers can be networked to support large plant systems.

When the sensor is connected to the versatile ECD T80 transmitter or the ECD LQ800 controller, the sensor’s information is automatically uploaded to the analyzer. It then configures the displays and outputs of the transmitter to the values appropriate to the oil sensor’s measurement parameters. Its digital output communications are RS485/Modbus compatible.

The universal T80 Transmitters are available as either single channel or dual channel devices, allowing one analyzer to measure up to two parameters or two ranges. This transmitter is available in a 24 VDC or a 100/240 VAC power configuration. All versions are available with an optional HART output to support integration with larger control systems.

The highly scalable eight-channel LQ800 Multi-Channel Controller is designed to operate up to eight ECD digital analytical and process sensors. Its flexible design features Modbus communications, with optional HART, and is Cloud-ready allowing integration with larger systems. The LQ800 Controller is available as a 24 VDC or 100/240 VAC powered controller.

Fluid Handling Magazine, OIW80 Sensor, Nov. 30

The new OIW80 Sensor from Electro-Chemical Devices (ECD) has given a boost to engineers at municipal water or wastewater facilities and industrial plants.

The new OIW80 Sensor from Electro-Chemical Devices (ECD) has given a boost to engineers at municipal water or wastewater facilities and industrial plants.

The devices help them to quickly detect oil in water leak incidents requiring fast response actions.

This prevents further contamination of drinking water, fouling of batch processes, damage to plant equipment and/or contamination of sensitive water ecosystems.

Oil in water is a serious issue for municipal drinking water and wastewater treatment.

Engineers must monitor operations for oil contamination from storm water, oil pipeline leaks, refinery spills or other industrial plant accidents.

Oil leaks can affect surface water from streams, rivers or lakes, as well as ground water and water storage systems such as reservoirs and storage tanks. Industrial plant engineers responsible for water-dependent processes, products and services also must worry about oil leaks.

Industries vulnerable to oil-in-water contamination include electric power, chemicals and more.

Oil-in-water leaks also can affects plant water re-use and effluent treatment processes prior to discharge.

The highly intelligent, precision OIW80 Sensor reliably measures oil in water over a range of 0 to 30 ppm (mg/L), and it can be factory preconfigured to measure oil in multiple ranges or easily set in the field.

This rugged, high-performance responsive sensor operates over a temperature range from 5oC to 45oC to quickly detect leaks and alert plant technicians.

Designed for demanding and/or dirty plant environments, the highly dependable OIW80 Sensor features a built-in wiper cleaning system to remove bio solids and films that might cloud the sensor window’s visibility. The sensor features a built-in automatic screen window wiper that reduces technician manual checks and the frequency of scheduled maintenance cleanings.

Smart DO Analyzer Helps Water Technicians Protect Water Quality in Surface and Tank Storage Systems

Preserving Aquatic Plants and Wildlife in Environmentally Sensitive Lakes, Streams, Ponds, Municipal Water Reservoir Storage, Fisheries & Hatcheries

Anaheim, CA—October 25, 2021—Water engineers, environmentalists and aquaculture technicians will find the S80-T80 Dissolved Oxygen Analyzer from Electro-Chemical Devices (ECD) helps them easily, accurately and economically measure dissolved oxygen (DO) levels to ensure they support sensitive ecosystems, as well as municipal water storage and fish farming.

Dissolved oxygen is the amount of oxygen that is naturally present in bodies of water. These water sources receive their oxygen from the atmosphere and from aquatic plants. Running water, such as that of a swift moving stream, dissolves more oxygen than the still water of a pond or lake. All aquatic animals such as fish need adequate levels of DO to breathe.

The easy-to-use, economical ECD S80-T80 DO Analyzer with its intelligent S80 sensors and intuitive T80 transmitter is the perfect solution for measurement. This analyzer comes pre-calibrated from the factory, requiring no special tools or installation training. It’s a plug-n-play system that’s ready-to-go out of the box and designed for busy water engineers and techs.

According to the U.S. Environmental Protection Agency (EPA), low levels of oxygen (hypoxia) or no oxygen levels (anoxia) can occur when excess organic materials, such as large algal blooms, are decomposed by microorganisms. During this decomposition process, DO in the water is consumed. Knowing DO levels allows technicians to remediate issues early on.

Low oxygen levels often occur in the bottom of the water column and affect organisms that live in the sediments. In some water bodies, DO levels fluctuate periodically, seasonally and even as part of the natural daily ecology of the aquatic resource. As DO levels drop, some sensitive animals might move away, decline in health or even die.

To prevent these issues, environmentalists, municipal water engineers and industrial technicians often must monitor DO levels—especially in municipal surface water storage systems consisting of reservoirs, lakes, ponds and tanks or enclosure pens for aqua-culture or fish hatcheries. Failure to maintain sufficient oxygen levels also can jeopardize municipal drinking water quality and jeopardize sensitive wildlife.

When the intelligent S80’s sensor is connected to the versatile T80 Transmitter, the sensor’s information is uploaded to the analyzer. It then configures the displays and outputs of the transmitter to the values appropriate to the DO sensor’s measurement parameters. The S80-T80 DO Analyzer measures dissolved oxygen levels from 0 to 20 ppm (mg/L) at 250 percent saturation. They operate over a pressure range of 0 to 50 psig and at temperatures (-5 to 80°C).

The standard S80 sensors have 316 Stainless Steel housings although various materials of construction are available to maximize sensor performance while minimizing cost of ownership. They are available in either a choice of insertion or valve retractable configurations for quick disconnect and replacement of sensor cartridges.

The universal T80 Transmitters are available as either single channel or dual channel instruments. This transmitter comes in a 24 VDC or a 100/240 VAC power configuration. All versions are available with the optional HART® output. These line powered instruments have one 4-20 mA output per channel and a MODBUS RTU. Other options include a three alarm relay package configurable as alarm (set point) relays, timer activated relays or fault relays.

ECD Analyzer Helps Municipalities & Manufacturers Get The Lead Out To Clean Up Water Supply

Ideal Solution for Helping Meet Latest U.S. EPA LCR Requirements, as well as European Union’s RoHS Directive 2002/95/EC

Anaheim, CA—September 27, 2021—Plant engineers responsible for clean, safe drinking water in their communities and those engineers in business tasked with industrial wastewater treatment will find that the S80-T80 Lead (Pb) Analyzer and S80-T80 Copper (Cu) Analyzer from Electro-Chemical Devices (ECD) helps them verify treated water quality.

The U.S Environmental Protection Agency (EPA) Lead and Copper Rule (LCR), updated in late 2020, is now in place for municipalities with lead pipes. These Pb testing requirements will extend to schools and other public facilities as well to protect youth and families. The EPA has estimated there are 6 to 10 million aging municipal water lead service lines and systems that must be tested and upgraded to prevent future Pb contamination of the water supply.

The electronics industry also has recognized for decades that water and soil contamination by lead and copper have been a problem in the manufacture of semiconductors, passive components and circuit boards. The EPA issued in 1983 its Electrical and Electronic Components (E&EC) Effluent Guidelines and Standards (40 CFR Part 469) to address the issue. In addition, electronics companies worldwide must adhere to the Restriction of Hazardous Substances (RoHS) regulations per European Union (EU) Directive 2002/95/EC.

To assist municipal and industrial process and plant engineers, ECD has developed a modular family of ion selective Pb and Cu analyzers. A wide array of ECD water quality sensors are also available for other municipal water needs, including Ammonium, Calcium, Chlorine, Chromium VI, Fluoride, Nitrate, Nitrite, Phosphates and Sulfur. Industrial sensors and systems are available for Bromide, Cadmium, Cyanide, Manganese, Nickel, Potassium, Silver and more.

When the intelligent S80 Pb ion selective sensor is connected to the versatile T80 Transmitter, the sensor’s information is uploaded to the analyzer. It then configures the displays and outputs of the transmitter to the values appropriate to the Pb sensor’s measurement parameters. The S80-T80 Pb Analyzer measures Pb over a range of 2.0 to 20,700 ppm at a pH level of 4-8 over a wide temperature range from 32 to 176°F (0 to 80°C) with a T90 response time of 10 seconds.

For copper monitoring, the Cu S80 Sensor is connected to the same, modular T80 Transmitter, with the ion-selective Cu sensor’s information uploaded to the analyzer. It also then configures the displays and outputs of the transmitter to the values appropriate to the Cu sensor’s measurement parameters. The highly sensitive S80 Cu sensor operates over an exceptionally wide measurement range of 1.0 ppb to 6,300 pm at a pH level of 2-4 over a temperature range 32 to 176°F (0 to 80°C) with aT90 response time of 10 seconds.

The versatile design of the ion-selective S80 sensor family can be specified for insertion, immersion or valve retractable service. Their rugged design is suitable for heavy-duty municipal and industrial applications and includes a choice of materials: 316 Stainless Steel, Titanium or Hastelloy. Maintenance is simple with a replaceable electronic cartridge, which can be performed by plant technicians without any special tools or training.

The universal T80 Transmitters are available as either single channel or dual channel instruments, allowing one analyzer to measure both Pb and Cu. This transmitter is available in a 24 VDC or a 100/240 VAC power configuration. All versions are available with the optional HART® output. The line powered instruments have one 4-20 mA output per channel and a MODBUS RTU. Other options available include a three alarm relay package. The relays can be configured as alarm (set point) relays, timer activated relays or fault relays.

Leave a Reply

Want to join the discussion?Feel free to contribute!