User-Friendly, Reliable ORP Sensors Lower Plant Operating Costs by Simplifying Measurement

Engineers and technicians searching for a high-performance, cost-effective ORP sensing solution will find that the S10 and S17 ORP Sensors from Electro-Chemical Devices (ECD) feature a no-glass design with platinum or gold sensor tips to operate safely in a wide range of the most demanding applications.

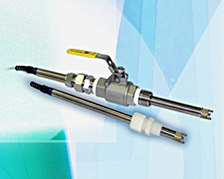

ECD’s ORP S10 and S17 Sensors come with easily replaceable ORP cartridges that plug into a rugged 316 stainless steel body, which incorporates the sensing element, a temperature module and a signal conditioner with cabling. The S10 is an immersion or insertion style sensor, and the S17 is a valve retractable style sensor.

ORP (oxidation reduction potential) refers to the tendency of a solution to gain or lose electrons when a new substance is introduced into it. The accurate measurement of ORP is useful in the treatment of municipal drinking water and municipal wastewater, as well as in a wide range of industrial processes with applications in petrochemical plants, electronics and semiconductor fabrication, metals and mining, biotech, pharmaceutical, power generation, aquatic parks and environmental monitoring systems.

ECD’s ORP electrode cartridge features rugged PEEK (polyetheretheketone) construction and measures from -2,000 to +2,000 millivolts over a wide temperature range of 23 to 176OF (-5 to 80OC). The ORP sensors are available with the SENTINEL option to monitor the reference electrode potential and display measurement drift graphically and/or with a 4-20 mA output providing a predictive maintenance alert before reference electrode degradation causes problems to occur.

The S10 and S17 sensors replaceable electrode cartridge also can be selected to measure pH, dissolved oxygen, conductivity and resistivity in addition to ORP. Featuring field proven construction materials selected for long life and accuracy, the cartridges provide specific solutions for the most demanding measurement requirements and support diverse industries with a variety of configurations and materials.

The S10 immersion or insertion style sensor is designed with a 0.75-inch MNPT compression fitting as the process connection. This construction feature allows a variable insertion length to accommodate installation in pipe tees, flow cells or through tank walls. If the trunk fitting is reversed, the sensor can be installed in a pipe for submersion in a tank.

The S17 retractable style sensor is designed with a 1-inch MNPT ball valve, a 1-x-0.75 inch reducer and a 0.75 inch MNPT compression fitting to provide the process connection. Loosening the compression fitting allows the sensor to side freely through the ball valve for insertion either into the process or retraction from the process. Once the sensor is retracted, the ball valve can be closed and the sensor can be removed for maintenance or replacement without shutting down the process line.

To create a complete ORP measurement system, the S10 and S17 Sensors also can be integrated with ECD’s C22 Analyzer. The Multi-Bus design enables customization of up to four inputs and six outputs in a convenient 1/2 DIN NEMA 4X enclosure. Channel comparisons or measurement compensation, configurable conductivity concentration curves, the graphical display of data and PID control on the outputs or up to 8 optional SPDT relays are just a few of the powerful features in this easy to use instrument.